Manage and Automate Warehouse with Warehouse Management

Warehouse management software provides complete control, management, and visibility of all logistics operations.

It enables optimally to manage distribution, production, real-time inventory updates, and integration with shipping systems.

The functionalities

- Automatic notifications about expected stock location or condition or other user-defined events.

- Captures and saves data to aid in identifying and eliminating problems in warehouse operations.

- Automatic tracking of data leaves no place for human error.

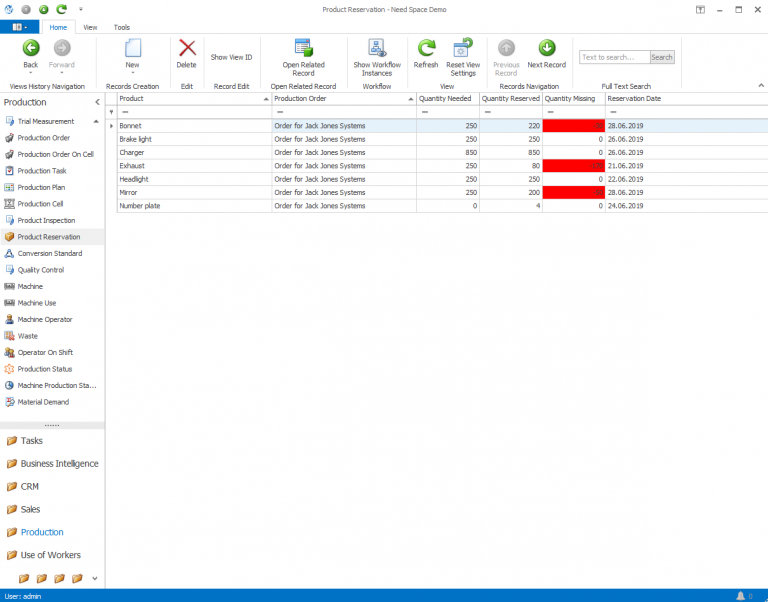

- Inventory management features to reduce stock losses and optimize stock utilisation.

- User-friendly with menu-driven applications

Optimise inventory, people, space, and equipment while minimizing cost. - Paperless order picking.

- Releases capital frozen in raw materials, enabling the precise ordering of quantities of materials corresponding to production needs.

- Accelerates workflow by introducing real-time status management in conjunction with a barcode system.

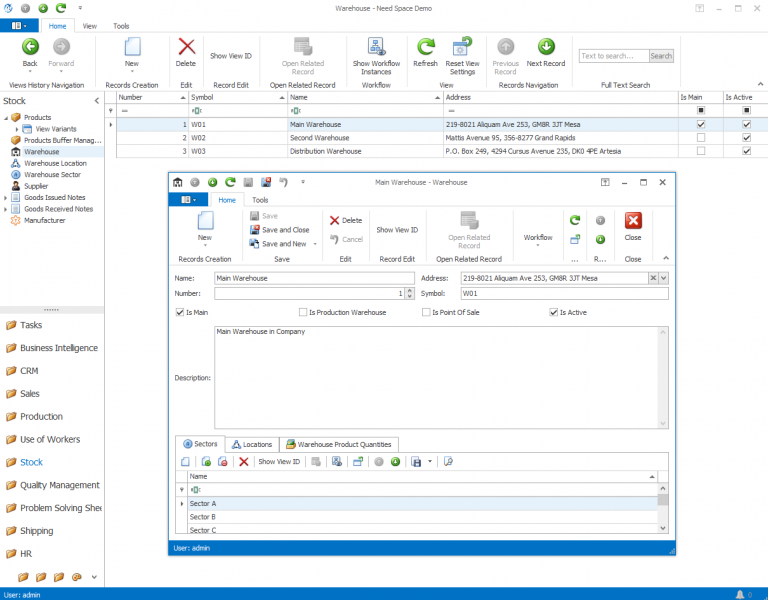

Organize your space with Warehouse Management

Controlling inventory, the quantity of raw materials in storage and costs is essential for success.

You need constantly pursuing to improve their warehouse operations by increasing agility, visibility, and efficiency.

Warehouse management software provides the functionality needed to address all aspects of your warehousing, distribution and production needs.

4 Key Features of Warehouse Management

Cost-reduction

Free up capital frozen in raw materials with precise production and supply planning. Efficient warehouse management will reduce the losses associated with the underutilisation of raw materials and the organisation of large warehouse space.

Integration with another system

Eliminates paper form processing makes the warehouse manage a less time-consuming task.

Integration with other systems, for example, production management system, allows even more precise planning of warehouse resources.

Simple management & planning

Plan and balance the number of orders, monitor the outbound progress, streamline picking-packing and dispatching, help warehouse managers to define labour standards so that operations are done on time and with utmost accuracy.

Easy Flow of Inventory

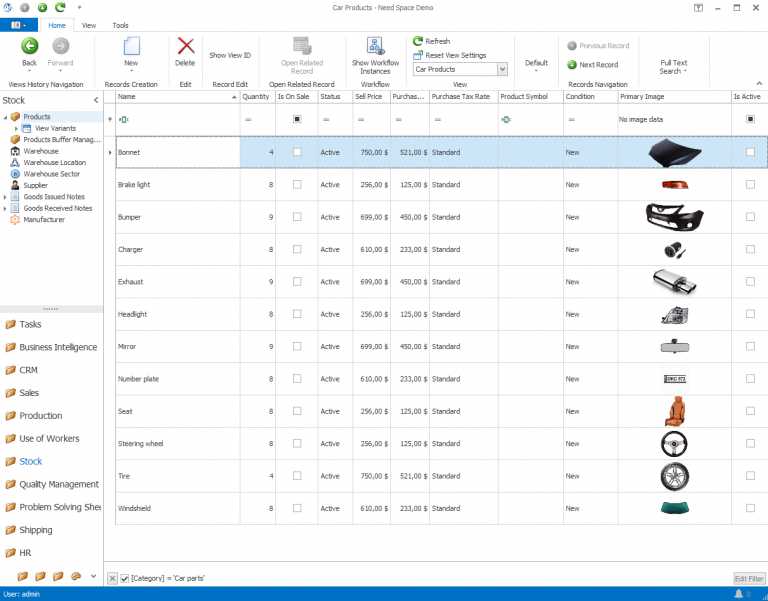

Lets you generate barcodes, print labels, view list of purchase orders, facilitate inside-company warehouse transfers.

The system will locate the goods in the warehouse after the barcode and the history of their storage.

CEO

Thanks to the precise planning of raw material consumption, the capital is frozen in raw materials and warehouse space will be released. Access to data in real-time and the possibility of integration with other systems allows making decisions and actions affecting the expansion of the company.

Managers

Help to define labour standards so that operations are done on time and with utmost accuracy. They can plan raw material deliveries in accordance with the assumed production schedule.

employee

The system saves time spent on searching for resources in the warehouse and preparing and turning paper documentation. An increase in work efficiency and minimize human errors thanks to the barcode system, which stores all the most important information about a given product.